Understanding a Knock Sensor Wiring Diagram is crucial for anyone looking to diagnose or repair their vehicle's engine. This diagram provides a visual guide to how the knock sensor, a vital component in modern engine management, communicates with the engine control unit (ECU). Without a proper understanding of this wiring, troubleshooting issues related to engine pinging or detonation can be a frustrating and inefficient process.

The Role and Function of a Knock Sensor Wiring Diagram

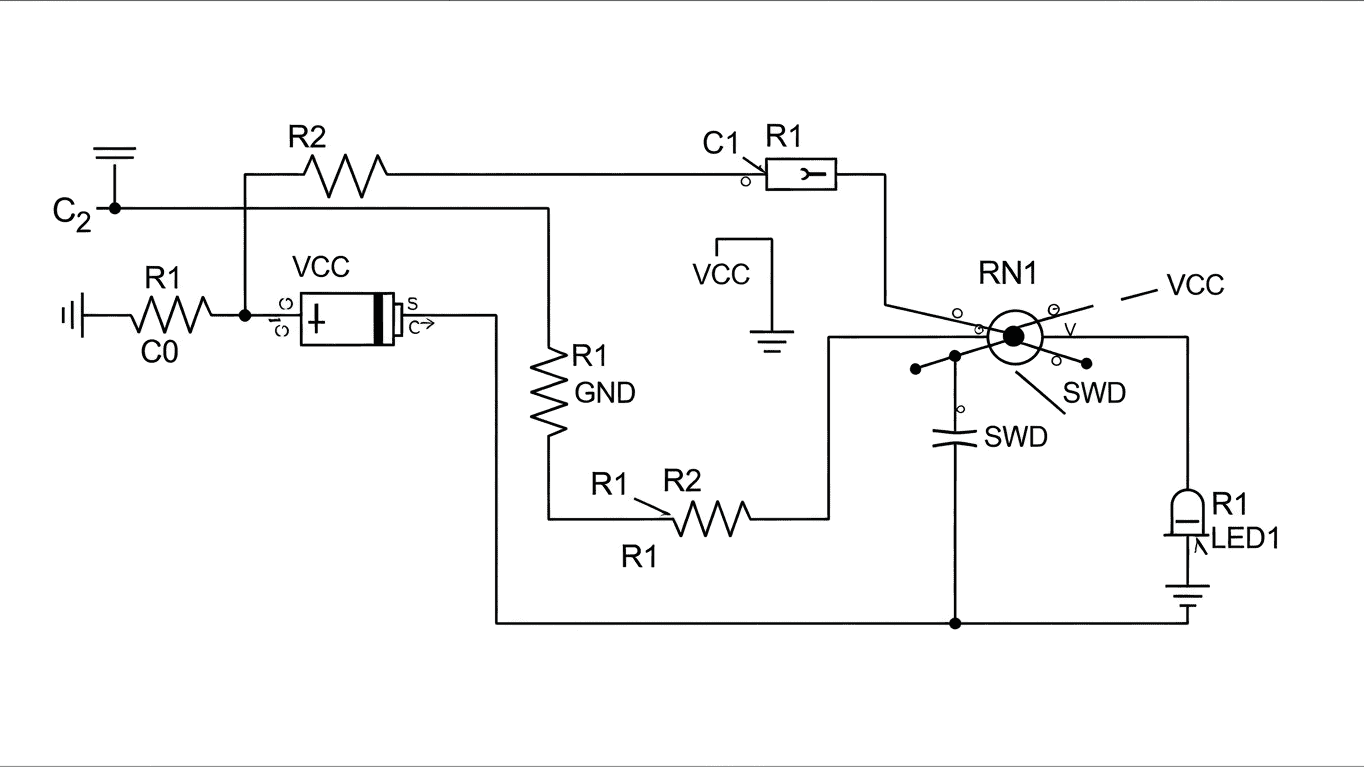

A knock sensor wiring diagram illustrates the electrical connections between the knock sensor itself and the vehicle's engine control unit (ECU). The knock sensor's primary function is to detect abnormal vibrations within the engine, often referred to as "knocking" or "pinging." These vibrations occur when the air-fuel mixture in a cylinder ignites prematurely or unevenly. The knock sensor, typically mounted directly to the engine block, is designed to be sensitive to these specific frequencies of vibration. When it detects such a knock, it generates a small electrical signal.

This signal is then transmitted through the wiring harness to the ECU. The ECU, in turn, interprets this signal and makes immediate adjustments to engine parameters to prevent further knocking. These adjustments can include retarding the ignition timing or altering the fuel mixture. The efficiency and accuracy of this entire process depend heavily on the integrity of the wiring. A faulty connection or damaged wire in the knock sensor circuit can prevent the ECU from receiving the knock signal, or it can send erroneous data, leading to performance issues and potentially engine damage. Here's a simplified look at the typical components involved:

- Knock Sensor

- Wiring Harness (connecting sensor to ECU)

- Engine Control Unit (ECU)

The proper functioning of the knock sensor system, as depicted in its wiring diagram, is paramount for engine longevity and optimal performance.

Understanding the pathways shown in a Knock Sensor Wiring Diagram allows technicians and DIY enthusiasts to:

- Identify the correct wires for testing.

- Trace potential breaks or short circuits in the wiring.

- Verify proper grounding of the sensor.

- Confirm the correct pin assignments on the ECU connector.

For instance, a typical diagram might show a two-wire setup for the knock sensor:

| Wire Color | Function |

|---|---|

| Signal Wire | Transmits the vibration signal to the ECU |

| Ground Wire | Completes the electrical circuit |

By cross-referencing the specific diagram for your vehicle's make and model, you can gain a clear understanding of these connections and troubleshoot effectively.

For a detailed and accurate representation of your specific vehicle's knock sensor circuit, it is highly recommended to consult the wiring diagrams provided within your vehicle's service manual or a reputable automotive repair database.