Understanding a Loop Detector Wiring Diagram is crucial for anyone involved in traffic control, automated gate systems, or any application that requires sensing the presence of vehicles. This diagram serves as the blueprint, guiding the connection of the inductive loop, the detector itself, and the power source. A correctly interpreted Loop Detector Wiring Diagram ensures reliable operation and efficient functionality.

What is a Loop Detector Wiring Diagram and How it Works

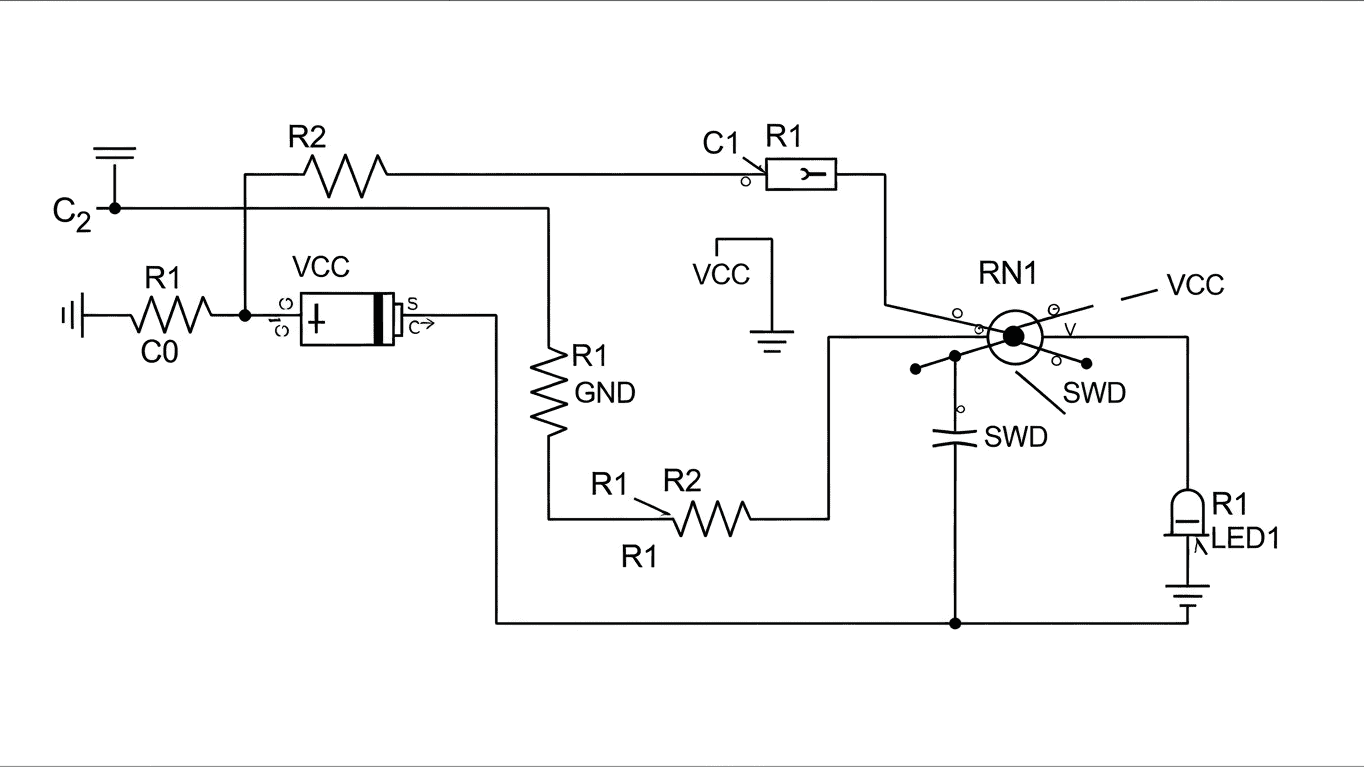

A Loop Detector Wiring Diagram is essentially a schematic that illustrates how to connect an inductive loop sensor to its corresponding detector unit. This system relies on the principle of electromagnetic induction. When a vehicle, which is a metallic object, passes over or comes to a stop above the buried loop of wire, it alters the magnetic field generated by the loop. The detector unit senses this change and triggers an output signal, indicating the presence of the vehicle. The accuracy and reliability of this detection process are directly dependent on the correct implementation of the Loop Detector Wiring Diagram.

The typical components you'll find represented in a Loop Detector Wiring Diagram include:

- The inductive loop itself (a coil of wire buried in the ground).

- The loop detector module (the electronic unit that processes the signal).

- Power supply connections.

- Output connections to a gate operator, traffic light controller, or other signaling device.

The way these components are interconnected varies slightly depending on the specific model of detector and the complexity of the application. However, the fundamental principles remain consistent across most Loop Detector Wiring Diagram examples. For instance, a simple setup might look like this:

| Component | Connection Point |

|---|---|

| Inductive Loop | Detector Terminals (e.g., L1, L2, L3, L4) |

| Power Supply | Detector Power Terminals (e.g., AC+, AC-) |

| Output Relay | Detector Output Terminals (e.g., NO, NC, COM) |

When planning an installation, a detailed Loop Detector Wiring Diagram is indispensable. It helps technicians understand the required wire gauge, the number of turns in the loop, the loop's dimensions, and how to properly terminate the loop wires to the detector. Failing to adhere to the guidelines presented in the Loop Detector Wiring Diagram can lead to false triggers, missed detections, or even damage to the equipment. It's also important to consider the environment and potential sources of interference, which are often addressed in more advanced diagrams or application notes.

For a clear and comprehensive understanding of how to wire your loop detector system, consult the specific Loop Detector Wiring Diagram provided by the manufacturer of your equipment. This will ensure a safe and effective installation, maximizing the performance of your vehicle detection system.