The Ls Bench Harness Wiring Diagram is a critical tool for anyone working with General Motors LS engine swaps or custom LS engine builds. This diagram provides a visual roadmap, detailing the connections required to power up and run an LS engine outside of its original vehicle. Understanding and correctly interpreting an Ls Bench Harness Wiring Diagram is essential for a successful and safe engine setup.

Understanding the Ls Bench Harness Wiring Diagram

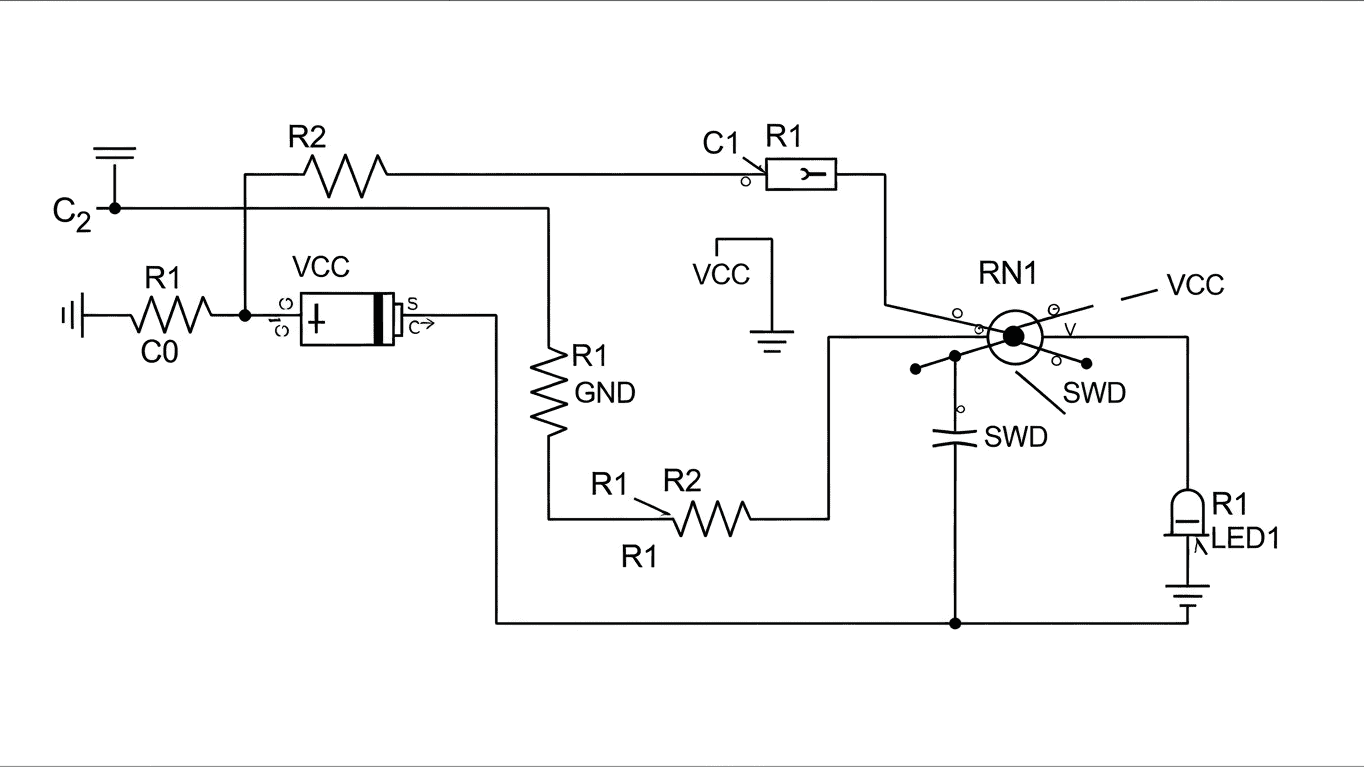

An Ls Bench Harness Wiring Diagram is essentially a blueprint that illustrates how to connect all the necessary electrical components to operate an LS engine on a test bench or in a standalone application. This typically includes the engine control module (ECM), fuel pump, ignition coils, injectors, sensors, and power and ground connections. Without this diagram, attempting to wire up an LS engine would be a complex and error-prone process. The importance of having an accurate Ls Bench Harness Wiring Diagram cannot be overstated , as incorrect wiring can lead to component damage, engine malfunction, or even fire hazards.

These diagrams are crucial for several reasons. Firstly, they simplify a very complex electrical system into manageable connections. You can see at a glance which wires go to which components. Secondly, they allow for pre-testing and troubleshooting of the engine before it's installed in a vehicle. This means you can identify and fix issues while the engine is easily accessible on the bench, saving considerable time and effort during the final installation. Common components you'll find represented on the diagram include:

- Engine Control Module (ECM)

- Fuel Pump Relay and Pump

- Ignition Coils and Spark Plugs

- Fuel Injectors

- Various Sensors (e.g., Crankshaft Position, Camshaft Position, Coolant Temperature, Oxygen Sensors)

- Throttle Position Sensor (TPS) and Idle Air Control (IAC)

The process of using an Ls Bench Harness Wiring Diagram usually involves:

- Identifying the specific LS engine variant you are working with, as wiring can differ slightly between models.

- Gathering the necessary wiring harness components or fabricating a custom one.

- Following the diagram step-by-step to make all the required connections.

- Ensuring proper grounds are established, as this is a common point of failure.

- Connecting a compatible power source and a diagnostic tool to check for communication with the ECM.

Here's a simplified look at some core connections you might find in a table format:

| Component | Typical Connection |

|---|---|

| ECM Power | Battery +12V (often with an ignition switch controlled relay) |

| ECM Ground | Chassis/Engine Block Ground |

| Fuel Pump | Switched +12V (via fuel pump relay) |

| Ignition Coils | ECM control signal and +12V power |

Having a reliable source for your Ls Bench Harness Wiring Diagram is key to a smooth build. For detailed and specific wiring diagrams tailored to various LS engines, we recommend referring to the resource provided in the section that follows.