Understanding your Meyer plow's functionality often hinges on a clear grasp of the Meyer Plow Controller Wiring Diagram. This diagram is your roadmap to how electrical signals travel from your controller to the various hydraulic and lighting components of your snowplow, ensuring it operates smoothly and effectively during those crucial winter months. Knowing where to find and how to interpret this diagram can save you time and frustration when troubleshooting or performing maintenance on your Meyer plow system.

Understanding Your Meyer Plow Controller Wiring Diagram

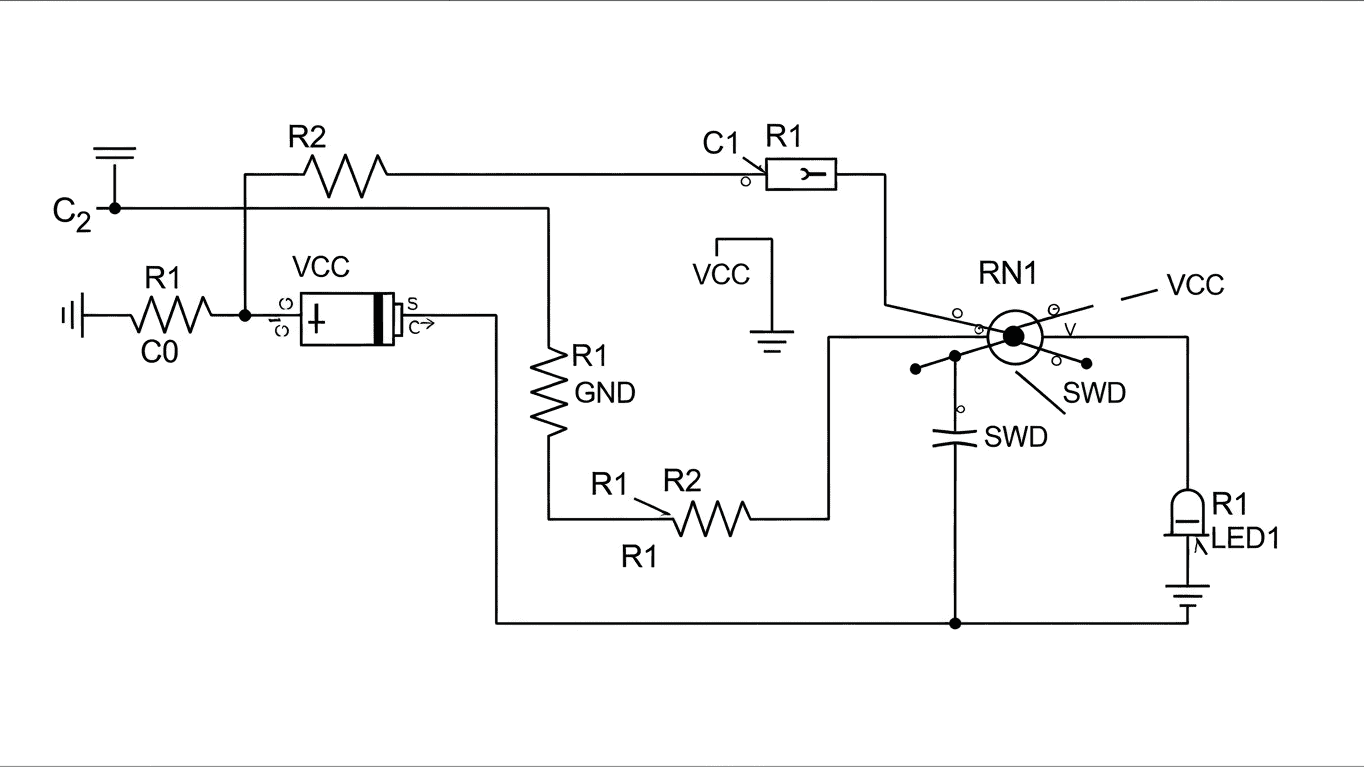

A Meyer Plow Controller Wiring Diagram is essentially a schematic that visually represents all the electrical connections within your snowplow's control system. It details the wires, their colors, their corresponding functions, and how they connect from the plow controller inside your vehicle to the solenoids, motors, lights, and other electrical parts of the plow itself. This diagram is an indispensable tool for anyone who needs to understand the electrical flow, diagnose issues, or make modifications to their Meyer plow. The importance of having and correctly interpreting this diagram cannot be overstated for proper system function and safety.

These diagrams are typically provided by Meyer Snowplows with their plow systems, often found in the owner's manual or available for download on their official website. They serve multiple purposes. For a technician, it's the primary reference for pinpointing faults. For a homeowner who enjoys maintaining their own equipment, it allows for a systematic approach to checking connections. Common elements you'll find depicted include:

- The controller unit itself.

- Power sources (e.g., vehicle battery connection).

- Relays and fuses.

- Solenoid valve connections for hydraulic control.

- Wiring harnesses and their routing.

- Connections for lights (headlights, strobes).

When you encounter a problem, like a plow that won't lift or angle, the Meyer Plow Controller Wiring Diagram becomes your best friend. You can use it to trace the signal path. For instance, if the lift function isn't working:

- Check the power supply to the controller.

- Verify the controller's output signal for the lift solenoid.

- Inspect the wiring to the lift solenoid.

- Confirm the solenoid itself is functioning.

Below is a simplified representation of how common components might be interconnected on a typical diagram:

| Controller Output | Component | Function |

|---|---|---|

| Lift Up Signal | Lift Solenoid | Engages hydraulic pump for lifting |

| Angle Left Signal | Angle Left Solenoid | Controls hydraulic valve for left angling |

| Power Input | Vehicle Battery | Provides electricity to the entire system |

By carefully consulting the specific Meyer Plow Controller Wiring Diagram for your model, you can systematically troubleshoot issues and ensure your plow operates at peak performance. The information contained within this diagram is crucial for maintaining the longevity and functionality of your snowplow system.

For the most accurate and detailed information tailored to your specific Meyer plow model, always refer to the official Meyer Plow Controller Wiring Diagram provided by the manufacturer. This resource will offer the precise wire colors, pinouts, and connection points you need to effectively work on your plow's electrical system.